introduce

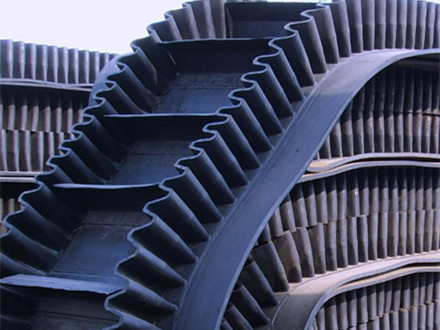

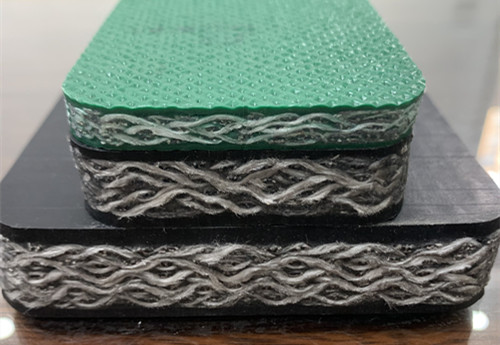

The steel wire conveyor belt is a rubber conveyor belt with steel wire as the skeleton. It has the advantages of high tensile strength, good impact resistance, long service life, small elongation in use, good groove formation, and good flexibility resistance. It is suitable for conveying materials over long distances, large distances, and high speeds. This product is composed of core glue, steel wire rope, covering layer and edge glue.

use

Wire rope conveyor belts are suitable for material transportation under tear-proof conditions in coal mines, mines, ports, electric power, metallurgy, building materials and other industries. They can be used for long-distance, large-span, large-volume and high-speed material transportation.

Specification

The strength specifications (N/mm) of steel wire core lifting belts are: St630, St800, St1000, St1250, St1600, St2000, St2500, St3150, St3500, St4000, St4500, St5000, St5400

Width specifications (mm) are: 400, 450, 550, 600, 680, 800, 850, 1000, 1050, 1200, 1300, 1400, 1600, 1800, 2000, 2200, 2400, 2600, 2800

Steel wire rope core conveyor belt

1. Hang the steel wire rope according to the specifications, models, diameters, and numbers required in the process notice.

2. Arrange the left and right twisted steel wire ropes in order on the spindle frame, and the steel wire ropes should not be twisted or tangled.

3. The surface of the steel wire rope shall not have oil stains, corrosion, or debris.

4. Clean the top and bottom of the steel wire rope with gasoline or adhesive for 10 meters each, and air dry it.

5. On the width of the tape, the steel wire ropes should be evenly arranged, with a tolerance of ± 1.5mm for the center distance of the steel wire ropes. However, if the deviation of a single rope distance exceeds 1.5mm, it should not exceed 5% of the total number of steel wire ropes within 3.0mm.

6. Arrange the joints of the steel wire rope in order, with left twisting and left twisting, and right twisting and right twisting. When replacing small size straps with large size straps, auxiliary ropes should be used for traction.

7. Clamp the gripper and maintain the pressure above 10.0Mpa without slipping (generally 10% to 15% higher than the pressure of the small cylinder). The force on a single steel wire rope should be uniform and consistent. Before applying tension, each steel wire rope must be in the groove.

8. The process technical parameters of tension at each tension station must be strictly implemented in accordance with the technical notification requirements.

9. The tolerance between the diameter of the groove of the wire rope comb and the diameter of the wire rope used is: tolerance ± 0.30 for diameter ≤ 5.0mm, and tolerance ± 0.50 for rope diameter>5mm.

When cold pressing the first plate, a fixed center comb must be added before and after the cold pressing plate. The cold pressing pressure is 2.0-2.5Mpa, and the cold pressing time is more than 60 seconds. It is advisable to press and expose the 'invisible' steel wire rope.

11. The joint between the adhesive and the middle adhesive should be staggered by 100-200mm, and the overlap width of the same type of film should be 5-10mm, using a 20 ° -45 ° layered oblique overlap.

12. The cutting edge should be neat, and after cutting, use 1-2mm thick adhesive film of the same type to seal the edge; It is not allowed to release tension when cutting edges. The width tolerance on both sides of the strip is ± 3mm.

13. The corresponding standards for the thickness and width of the billet and the finished product are detailed in the "Steel Wire Rope Core Conveyor Belt Process Regulations" or process notification.

14. The vulcanization temperature, pressure, time, and temperature of the cold plate head shall be executed according to the requirements of the production process sheet.

15. The quality of finished tape repair must strictly follow the process requirements and the "Tape Inspection and Repair Specification".

Friendly reminder:

1. We can make any type of rubber conveyor belt.

2. We have complete procedures and can mail to anywhere in the world.

3. All products support customization.