Product introduction

This product is mainly suitable for underground transportation in coal mines, and can also be used for material transportation in the metallurgical and chemical industries. Whole-core flame-retardant conveyor belts can be divided into PVC type and PVG type.

The upper and lower covering layers of the PVC type are both PVC cover glue, and the single-sided adhesive tape is ≥0.8mm; the upper and lower covering layers of the PVG type are both nitrile rubber and PVC, and the single-sided thickness is 1.5mm-4.5mm. The transportation inclination angle of PVC conveyor belts is < 16°, and the transportation inclination angle of PVG conveyor belts is < 20°, both of which can be used for both above and underground transportation in coal mines.

Production process

Flame-retardant conveyor belt production process: drying→plasticizing→combining→mixing→parking→heating→calendering→forming→vulcanization→packaging. Different from non-nylon skeleton conveyor belts, the production process of nylon layered flame-retardant conveyor belts requires secondary stretching and shaping after vulcanization. There are two main methods for secondary stretching and shaping, one is the cooling and shaping method under pressure inside the mold (hereinafter referred to as in-mold shaping), and the other is the outside-mold stretching and cooling shaping method (hereinafter referred to as outside-mold shaping). The in-mold shaping method is simple and has good shaping effect. However, this method consumes a lot of energy and has low production efficiency. In contrast, although the out-of-mold shaping method requires an additional stretching device, the product quality is reliable, the production efficiency is high, and it is suitable for mass production.

use

Mainly used in coal mines. Features of this belt: The belt body does not delaminate, has small elongation, is impact-resistant and tear-resistant. According to different knots, it can be divided into PVC type (plastic surface) and PVG type (rubber surface added on the basis of PVC) whole-core flame-retardant tapes, which comply with the MT914-2002 standard.

a. PVC flame-retardant conveyor belts are suitable for material transportation under dry conditions with an inclination angle of less than 16 degrees.

b.PVG flame retardant conveyor belt is suitable for conveying wet and watery materials with an inclination angle below 20 degrees.

(1) Model N/mm (tensile strength):

Level Level 4 Level 5 Level 6 Level 7 Level 8 Level 9 Level 10

Model 680s 800s 1000s 1250s 1400s 1600s 1800s

(2) Flame retardant performance:

a. Roller grinding number: The surface temperature of the roller shall not exceed 325°C.

b. Blowtorch combustion: The average flame-free time of the full-thickness specimen when removing the blowtorch is no more than 3.0S, and the average time when the covering layer is removed is no more than 5.0S.

c. Propane combustion: lossless length greater than 250mm

d.Safety performance:

The conveyor belt has passed flame retardant testing and electrostatic testing, and has obtained the coal safety mark of the certificate and customer approval.

This product uses an integral belt core as the skeleton material, which is made by impregnating and coating PVC materials with excellent antistatic and flame retardant properties and then plasticizing.

(4) The service life of the longest service life belt is determined by the following factors

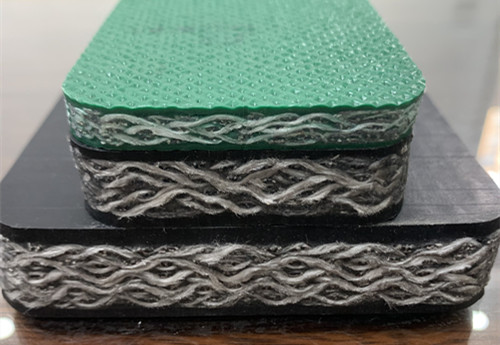

a. A dense belt core woven from warp and weft filaments and covered cotton;

b. Dip in specially formulated PVC material to achieve extremely high bonding strength between the core and the cover glue;

c. Specially formulated cover glue; thus making the belt resistant to impact, tearing and wear.

d. Product structure:

Flame-retardant conveyor belts use an integral belt core as the skeleton material, which is made by impregnating, coating and plasticizing PVC materials with excellent antistatic, flame-retardant and other properties.

Friendly reminder:

1. We can make any type of rubber conveyor belt.

2. We have complete procedures and can mail to anywhere in the world.

3. All products support customization.